Home » Electric electronic » TRAINING ROOM FOR DESIGNING AND MANUFACTURING PRINTED CIRCUITS

TRAINING ROOM FOR DESIGNING AND MANUFACTURING PRINTED CIRCUITS

TRAINING ROOM FOR DESIGNING AND MANUFACTURING PRINTED CIRCUITS

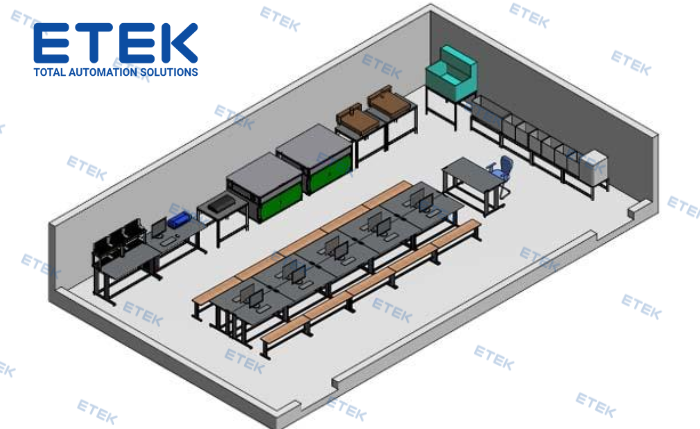

The Training Room for Designing and Manufacturing Printed Circuits (PCBs) provides hands-on experience in the entire process of PCB design, fabrication, and assembly. It is essential for students and professionals looking to gain expertise in electronics manufacturing.

FUNCTION

- Used to learn basic electronics theory

- Practice printed circuit manufacturing processes

- Practice the printed circuit design process

- Practice content about printed circuit design and manufacturing software for electronic circuit assembly tasks