Product Code: ST.HP.K1101

Price: Contact

– Learn the structure and operating principles of pneumatic and electro-pneumatic elements in practice

– Usage of elements

– Understand and draw circuit diagrams for valves and cylinders according to the application

– How to operate a single cylinder, the direction of action of a single cylinder, how to adjust the airflow through the 3/2 valve

– Direction of action of double-acting cylinder, how to operate 5/2 electric valve

– Direction of action of double-acting cylinder, how to operate 5/2 electric valve

– Programming and controlling cylinders based on electrical signal feedback, how to use various types of trip detection sensors in practice

– Practice simulating the principles of some real-life applications

– Connecting compressed air circuits:

+ Theory of compressed air

+ Sorting equipment

+ Switching device

+ Object rotation mechanism on the conveyor belt

+ Lid closing mechanism

+ Assembly station

+ Cutting machine structure

+ Barrel tilt control

+ Tilting structure

+ Product redirection device

+ Impeller valve control structure

+ The bar feeder uses gravity

+ Gravity feeder has many grooves

+ Conveyor control device

+ Product labeling rotary table

+ Sliding table

+ Clamping device

+ Direction reversing device

+ Pressing equipment

+ Heat sealing equipment

+ Moving station

+ Product classification (throttle valve practice)

+ Classification equipment (OR valve practice)

+ Stamping equipment (AND valve practice)

+ Bar feeding device (time relay practice)

– Skills in calculating pneumatic drive systems

– Skills in analyzing problems, choosing appropriate equipment and appropriate control methods

– Skills to find the cause of damage, grasp error phenomena and make decisions to solve problems

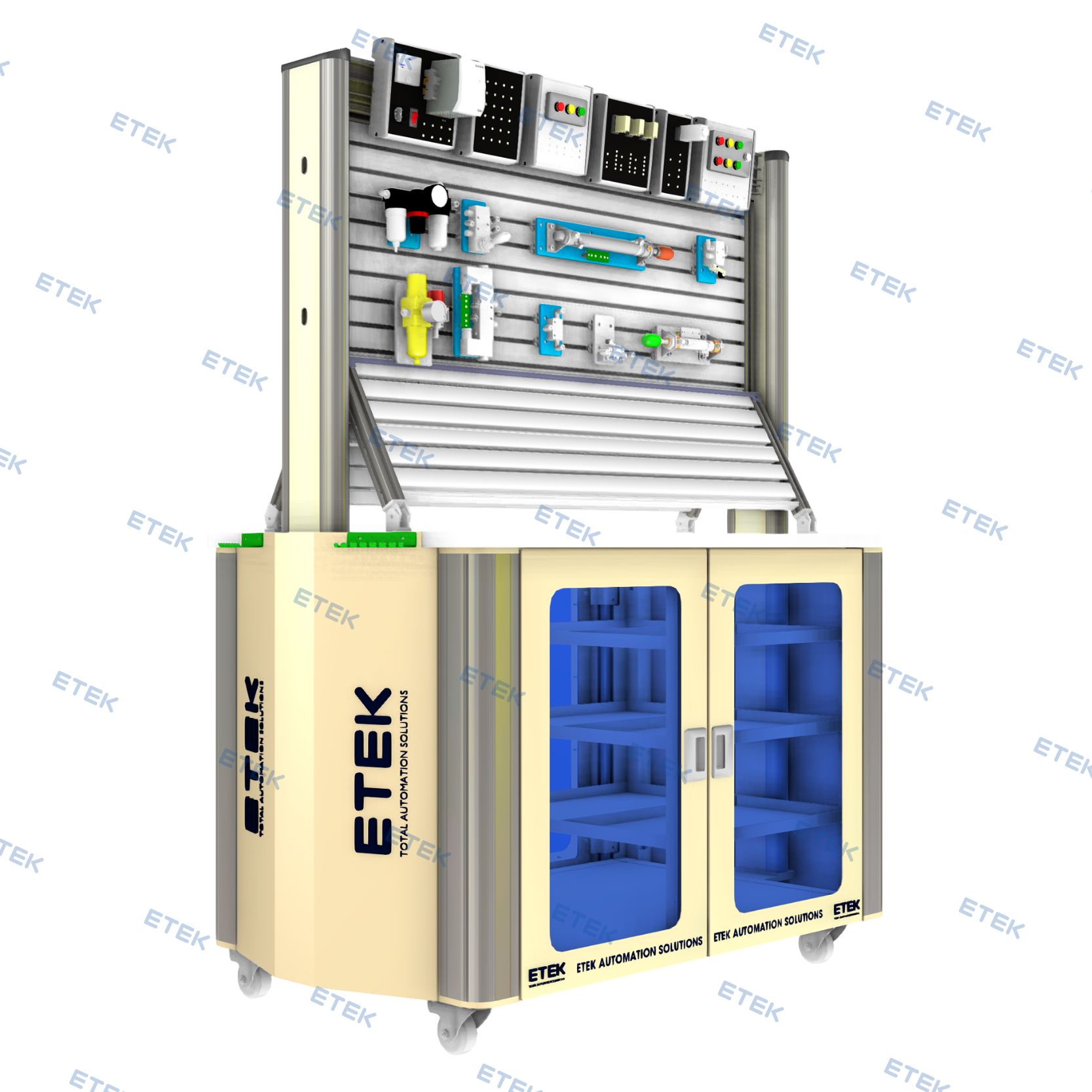

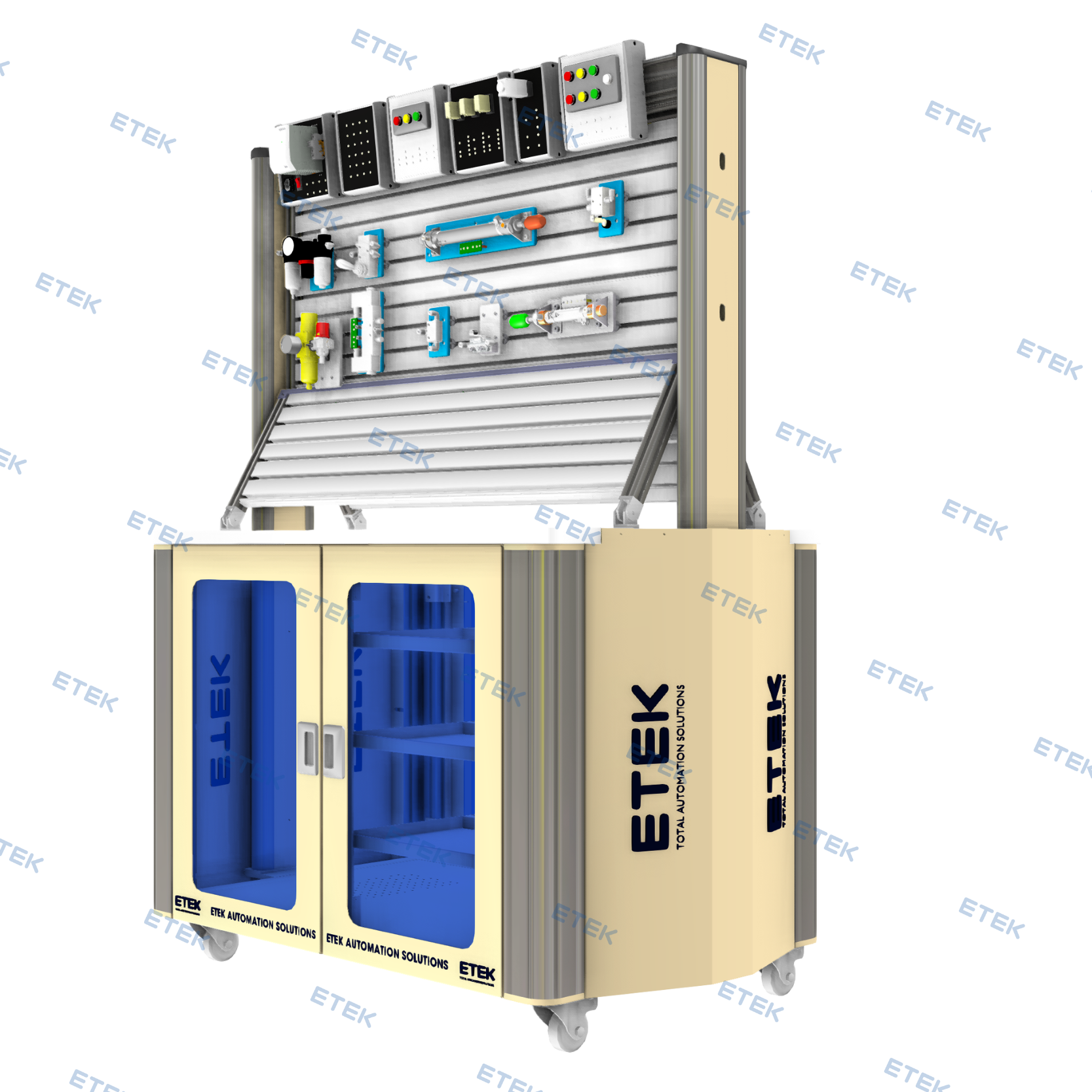

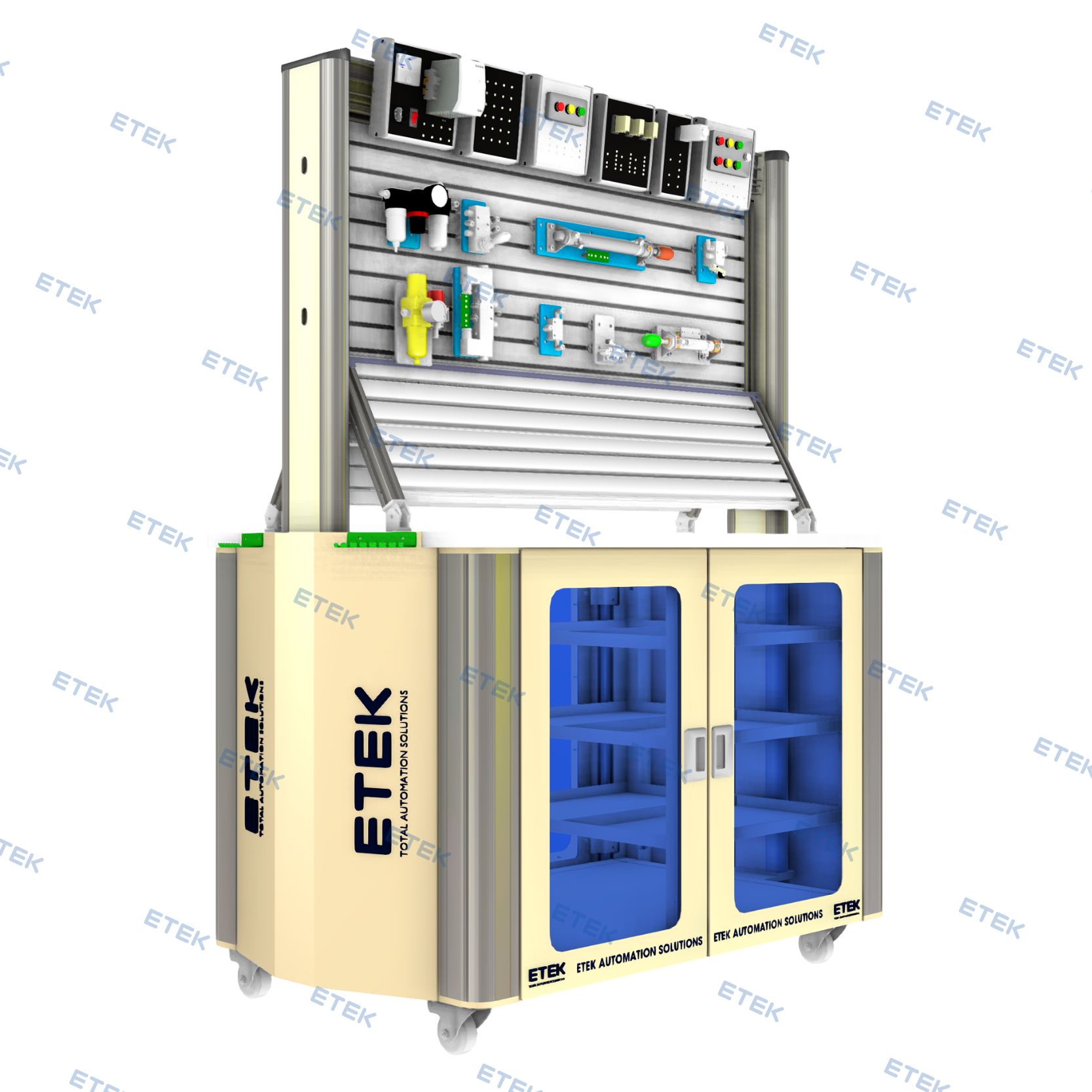

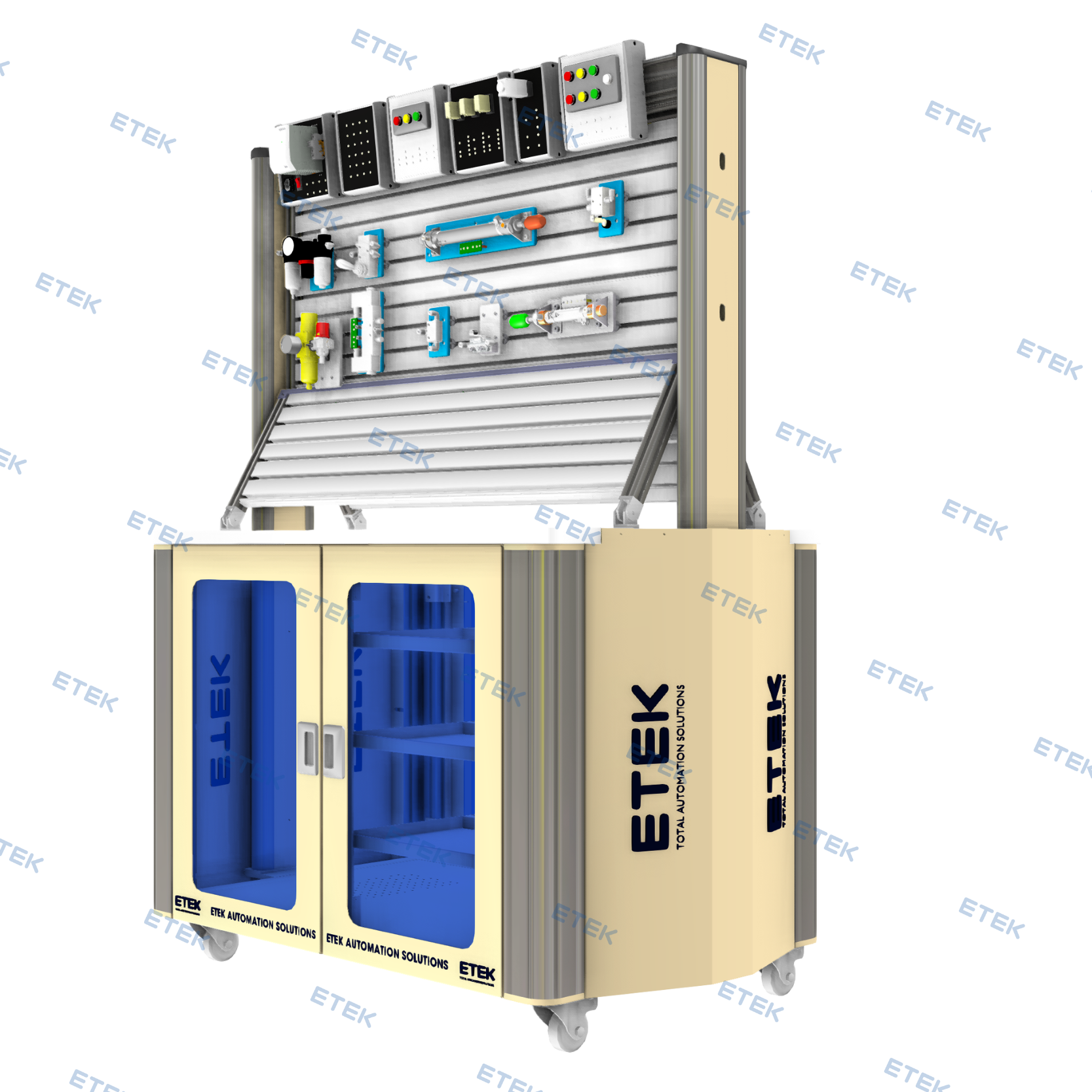

• The equipment set is designed as separate modules with standardized

dimensions and consistent connection interfaces, enabling flexible

configuration and easy upgrades.

• Pneumatic components are sourced from SMC Japan (global origin).

• Mounting base is made of scratch resistant aluminum alloy with ABS

self-locking plastic feet, featuring a cylindrical top with a “+” slot for

elasticity.

• The design allows quick installation and removal on the practice table,

thanks to self-locking plastic feet.

• Control modules include integrated plastic mounts and 2mm plug-in

connections for electrical wiring.