Product Code: ST.HP.T0101

Price: Contact

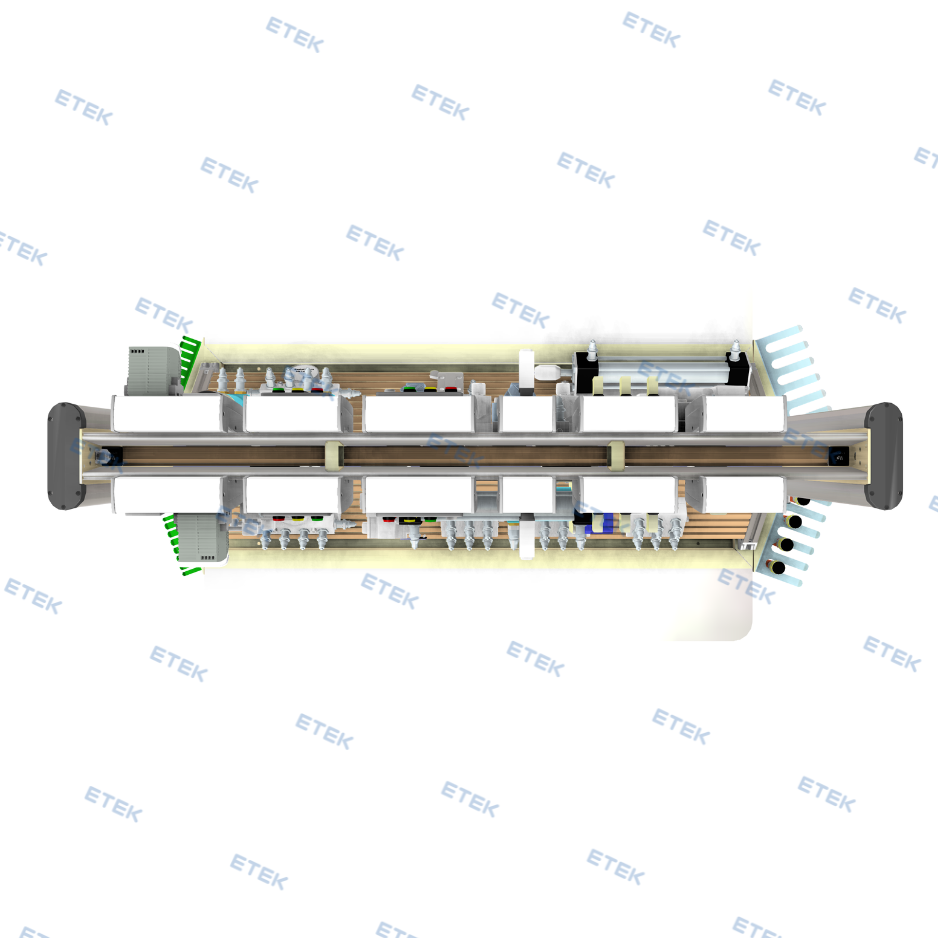

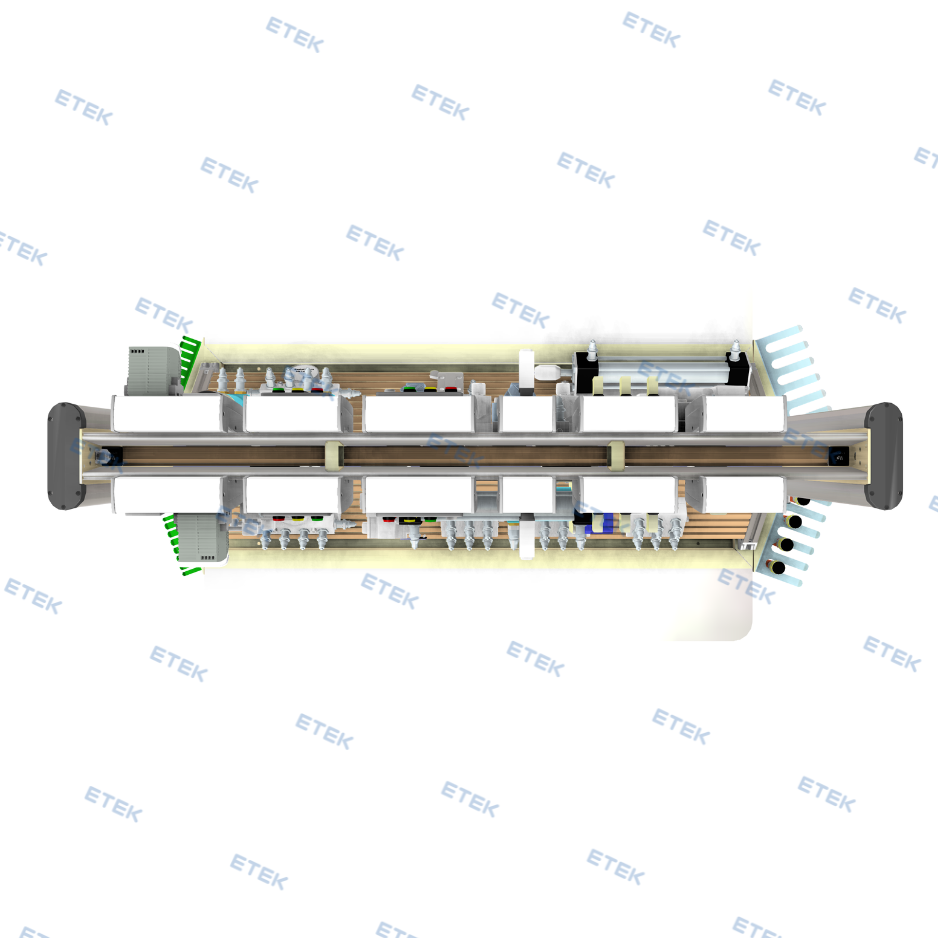

A Basic Hydraulic Practice Set is an educational or training tool designed to demonstrate the principles of hydraulic systems.

• Physical principles of hydraulics.

• Characteristics of hydraulic pressure and flow

• Pressure reduction on hydraulic pipes

• Learn the functions and uses of hydraulic valves and

other components.

• Control of basic hydraulic systems

• Understand and redraw existing hydraulic circuit diagrams

• Practice with hydraulic components

Assembly and operation of control circuits:

• Lesson 1: Automatic lathe

• Lesson 2: Package lifting device

• Lesson 3: Punching machine

• Lesson 4: Billet feeding device for rolling mill

• Lesson 5: Heat treatment furnace lid lifting device

• Lesson 6: Control of furnace door

• Lesson 7: Conveyor belt tensioner

• Lesson 8: Cold storage door opening and closing device

• Lesson 9: Processing station with turntable

• Lesson 10: Paint booth

• Lesson 11: Embossing machine

• Lesson 12: Surface grinder

• Lesson 13: Drilling machine

• Lesson 14: Combustion chamber door opening and closing device

• Lesson 15: Ferry bridge lifting device

• Lesson 16: Container operation

• Basic skills on operating principles, calculation methods of hydraulic transmission systems and control systems, knowing how to build system control circuits

• Thinking skills, design purposes, design thinking, analysis

• Skills to find the cause of damage and solve problems occurring in hydraulic circuits

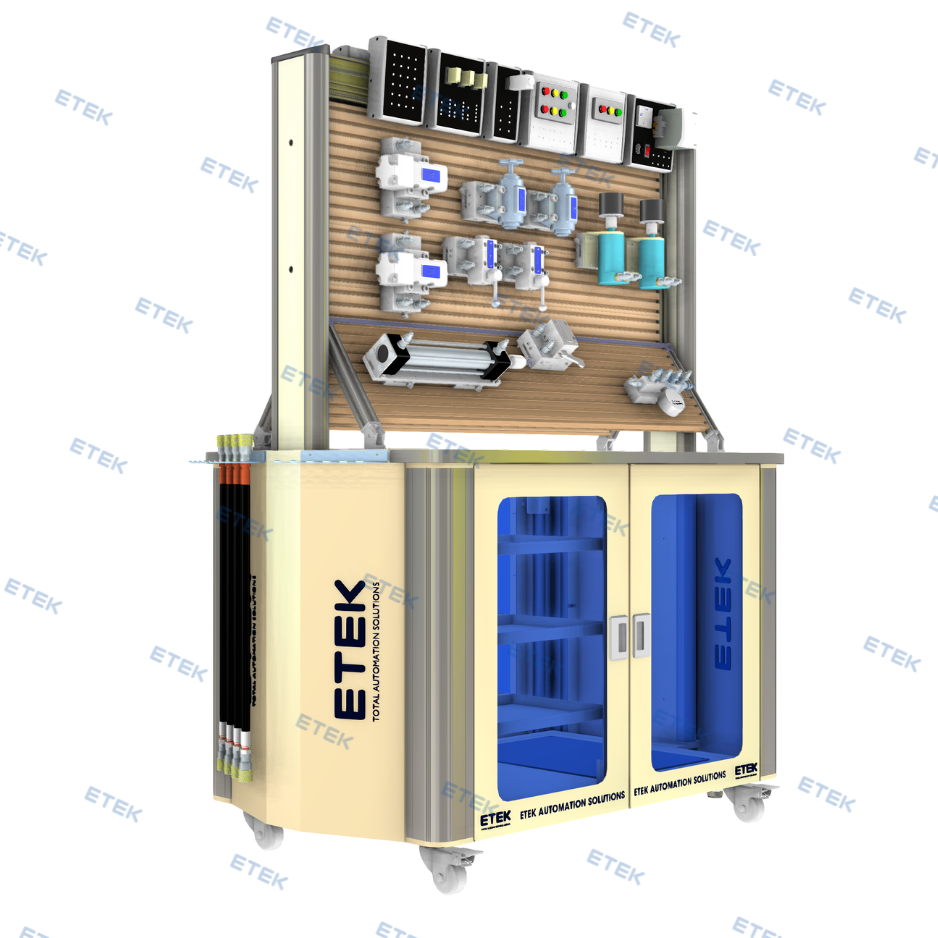

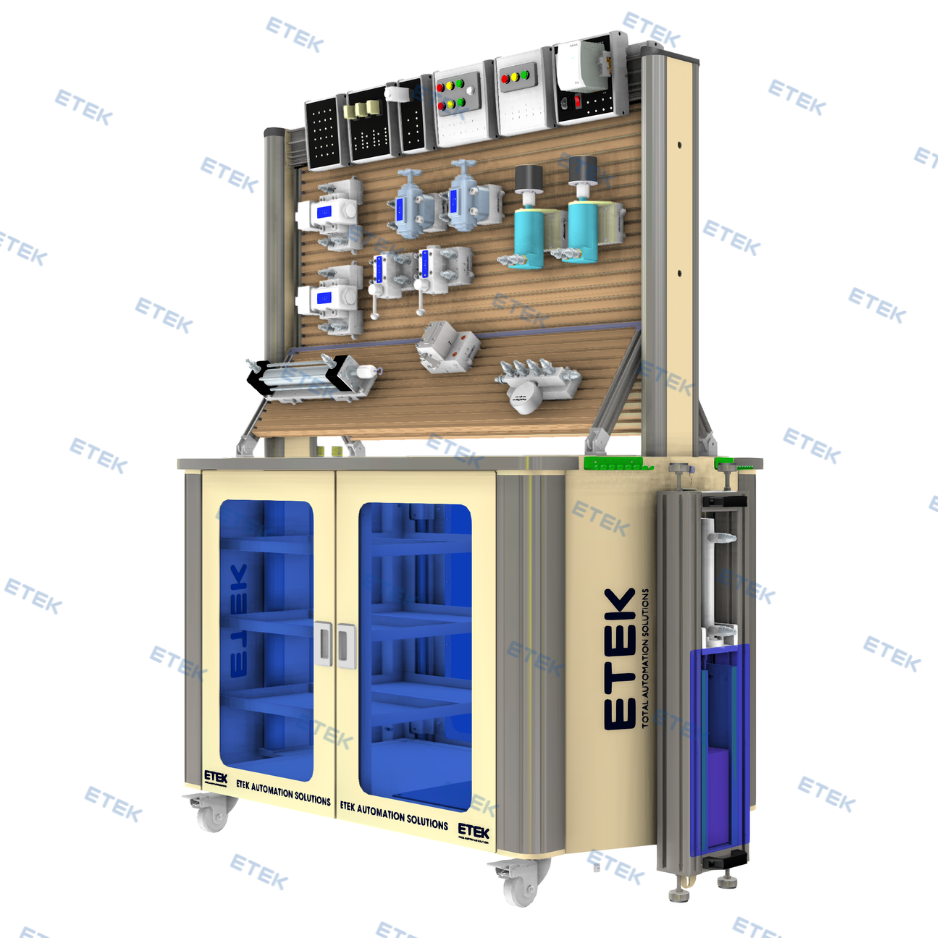

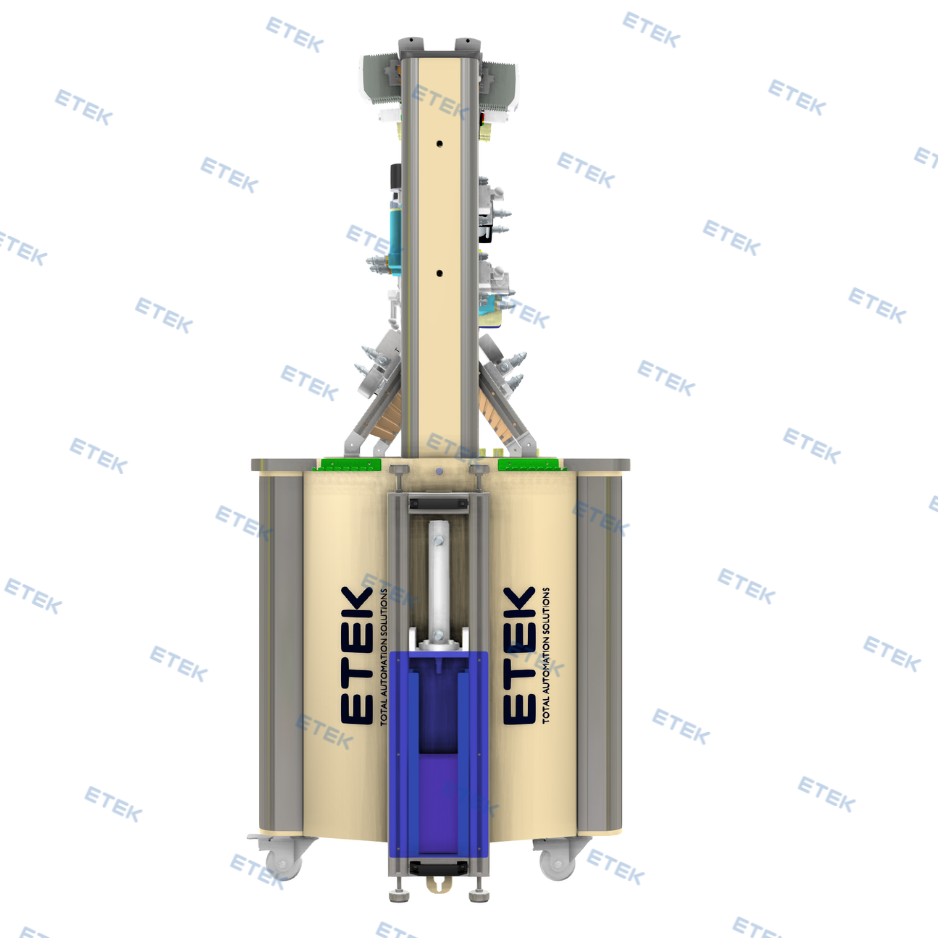

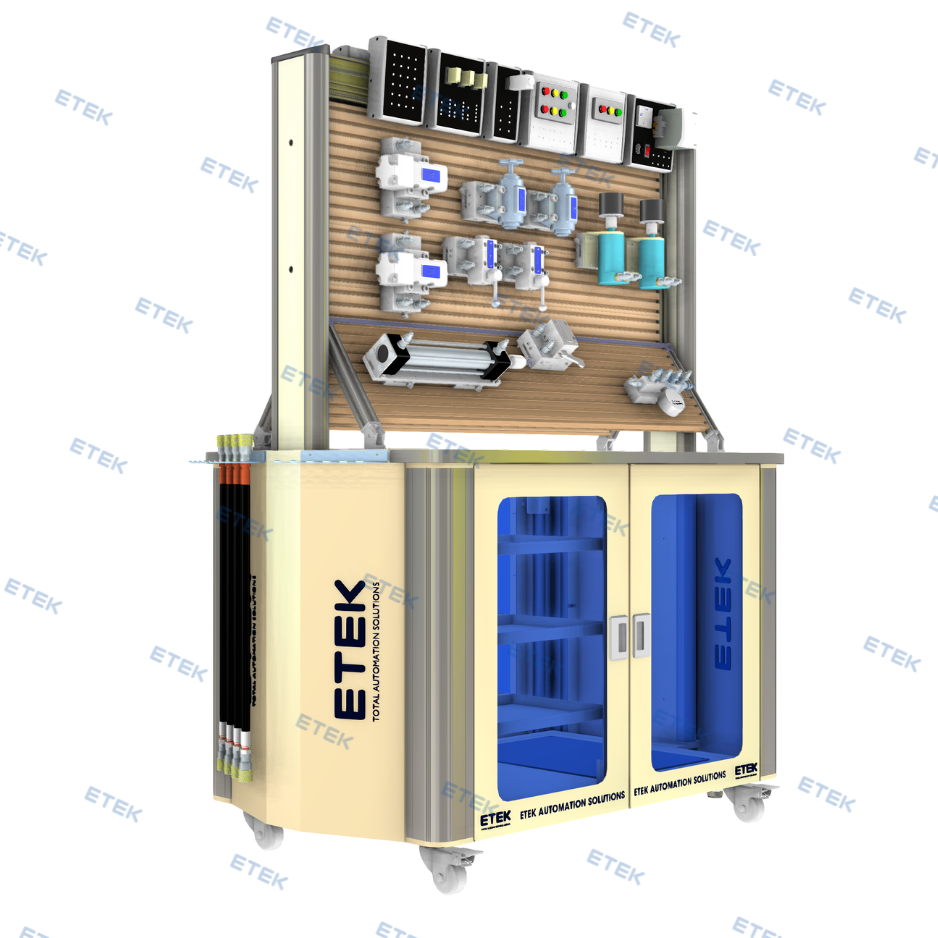

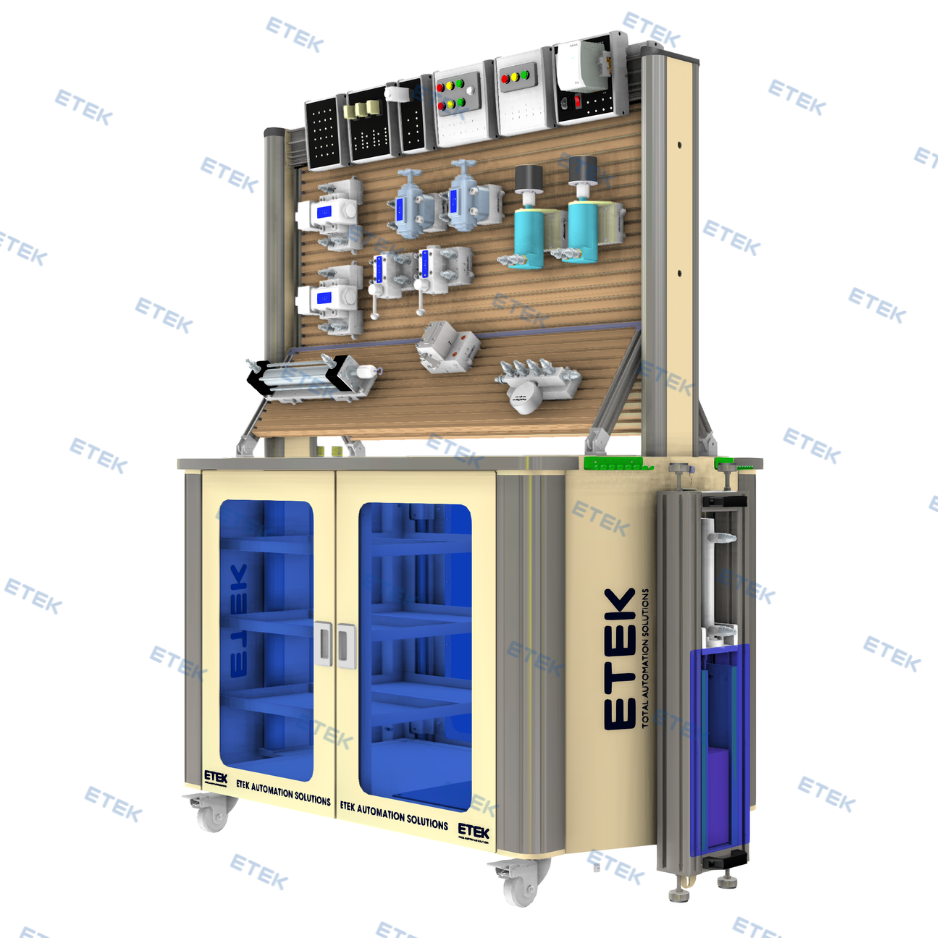

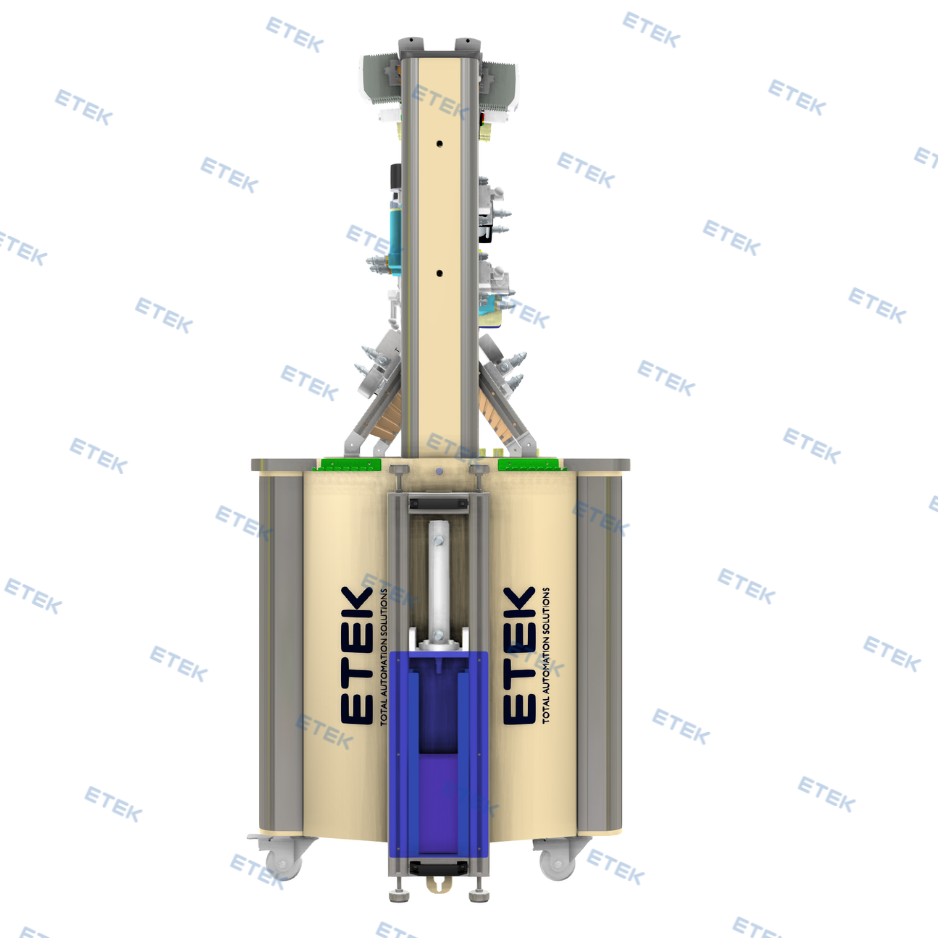

• The equipment set is designed into separate modules with standard sizes and the same connection standards, helping to flexibly connect equipment during practice and easily

upgrade products.

• The hydraulic equipment mounting base is machined from solid aluminum, anodized surface ensures hardness, durability and aesthetics.

• The modules in the practice set are manufactured according to ISO 9001:2015 Quality Management standards • The module has a built-in plastic mounting foot set:

• The mounting foot set uses a gear mechanism connecting the lever and the plastic foot.

• The plastic mounting foot is rectangular; the locking operation is by rotating the brake lever 90 degrees to easily insert it into the aluminum groove and lock it.